|

Volume 1

Click on the projector to view all images as a Slideshow

| 30 January 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Ken Cannane and

Frank Bowden began unpacking, sorting and researching the aircraft

maintenance records at Specialist Aviation at Kimpton where they were

being stored on behalf of the previous operator. This task was completed

on 06 February 2006. During this period, the aircraft was inspected

at Southend. Where is Southend? The flight deck images shown above can be viewed in high resolution (2000 x 1500 pixels) Flight Deck Flight Engineer's Panel |

||||||||||||||||||||||||||||

| 24 June 2006 | ||||||||||||||||||||||||||||

| First members of Team #1 arrived at Southend. | ||||||||||||||||||||||||||||

| 26 June 2006 | ||||||||||||||||||||||||||||

| First inspection of the aircraft by Team #1. | ||||||||||||||||||||||||||||

| 27 Jun 2006 | ||||||||||||||||||||||||||||

| Ken Cannane and Frank Bowden returned to the U.K. to organise the maintenance documentation and to meet with the CAA Inspector responsible for the Essex area. | ||||||||||||||||||||||||||||

| 28 Jun 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| There

are now 10 engineers in the U.K. - Paul Wilkinson, Peter Elliott,

Alan Chong, Bob Hagon, Ken Cannane, Frank Bowden, Ben Hunter, Bob

Hodson, Denis Martin and Bob Phillips. QFM signed a contract to purchase Boeing 707-138B formerly VH-EBA. |

||||||||||||||||||||||||||||

| 29 June 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Work commenced on the aircraft. With the help of the London Southend Airport Fire Service, the aircraft was washed. The undercarriage oleo struts were deflated and reinflated without problems. | ||||||||||||||||||||||||||||

| 30 June 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| All external markings and colours were painted over leaving the aircraft all white. The aircraft maintenance records were collected from Hatfield. | ||||||||||||||||||||||||||||

| 01 July 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| The aircraft was opened up for airing and a small Australian flag was flown from the forward cabin door. | ||||||||||||||||||||||||||||

| 03 July 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| The aircraft was towed from its storage site of many years to an area adjacent to the ATC Lasham hangar. The rear airstairs were deployed. | ||||||||||||||||||||||||||||

| 04 July 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Various checks. | ||||||||||||||||||||||||||||

| 05 July 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

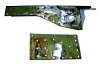

| All access panels were removed in preparation for NDT inspection of the wing spar. Commenced cleaning dried grease and dirt from flap tracks. No significant corrosion found. | ||||||||||||||||||||||||||||

| 06 July 2006 | ||||||||||||||||||||||||||||

| Fuel remaining on board (approx 10,000 pounds) was pumped around all tanks to check for leaks and to test the refuel system. All passed with no leaks. | ||||||||||||||||||||||||||||

| 07 July 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| The aircraft

was formally entered on the Australian Register as VH-XBA. The aircraft was moved to allow a B737 out of the hangar. |

||||||||||||||||||||||||||||

| 08 July 2006 | ||||||||||||||||||||||||||||

| Ken Cannane and Frank Bowden returned to Australia. | ||||||||||||||||||||||||||||

| 10 July 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Vulcan XL426 belonging to the Southend based Vulcan Restoration Trust was towed up behind VH-XBA and approximately 9,500 pounds of fuel was transferred to the Vulcan as a donation. This fuel will be consumed in one of the VRT's regular fast taxy runs on 12 August to commemorate the 20th anniversary of the Vulcan's arrival at Southend. Coincidentally, the Vulcan is registered G-VJET. Given that the Vulcan design was tested by the smaller Avro 707 research aircraft, it is appropriate that a 707 should give succour to a Vulcan. Clearly they are both type A1. | ||||||||||||||||||||||||||||

| 11 July 2006 | ||||||||||||||||||||||||||||

| Fuel tanks have been totally drained, opened and vented with blowers prior to inspection. Inspection of engine control cables and pulleys was satisfactory. The pitot static system has been purged and mapped. Cleaning of flap tracks has been completed and no significant corrosion found. The trailing edge flaps have been reassembled and are ready for hydraulic testing when a rig is available. The aircraft now wears a decal adjacent to the forward entry door stating that it is "Owned and operated by the Qantas Foundation Memorial Ltd." | ||||||||||||||||||||||||||||

| 12 July 2006 | ||||||||||||||||||||||||||||

| Pitot static system was checked for leaks. | ||||||||||||||||||||||||||||

| 13 July 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| The Australian registration VH-XBA was painted on the right side of the fin. All fuel tanks, including the centre wing tank, were inspected and declared serviceable. The pitot static system is presenting some difficulties. | ||||||||||||||||||||||||||||

| 14 July 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| The Australian registration VH-XBA was painted on the left side of the fin. Washing of fuel tanks to clear any contaminants almost complete. Hydraulic items have been ordered to repair leaks. The pitot static system is still presenting difficulties. The aircraft was towed to Bay 1 at the passenger terminal to allow movement of aircraft out of ATC Lasham hangar over the weekend. | ||||||||||||||||||||||||||||

| 17 July 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| 18 July 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| NDT inspection of spar caps commenced. A reception was held in the Downer Room at the Australian High Commission for team and sponsors. | ||||||||||||||||||||||||||||

| 19 July 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Corrosion was found in lower skins of rudder. Replacement panels were ordered from the U.S. | ||||||||||||||||||||||||||||

| 20 July 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| NDT inspection of the spar caps completed. Some areas of minor corrosion were treated and the aircraft will be issued with a clean bill of health. ATC Lasham offered the use of two crews gratis for two days to work on VH-XBA. This generous gesture saw the project move from four days behind to four days ahead of schedule. With the assistance of the ATC Lasham crews, it was possible to remove the lower right-hand rudder skin and inspect the lower closure rib. This revealed some minor corrosion which is repairable. The lubrication of the flaps has been completed. | ||||||||||||||||||||||||||||

| 21 July 2006 | ||||||||||||||||||||||||||||

| Undercarriage wash and lubrication scheduled to commence. | ||||||||||||||||||||||||||||

| 23 July 2006 | ||||||||||||||||||||||||||||

| Corrosion was found in rudder hinges. | ||||||||||||||||||||||||||||

| 24 July 2006 | ||||||||||||||||||||||||||||

| Corrosion was found in elevator hinges. This will necessitate folding the fin and removing the rudder and elevators to replace the hinges. | ||||||||||||||||||||||||||||

| 27 July 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| 02 August 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| 05 August 2006 | ||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "There are only 4 of us here at present and the workload is steady and manageable. This looks like dropping to 3, as Bob Phillips has just received news of his mother's failing health and Peter is working on getting him on tonight's QF2 back to be with her. We wish him well in this difficult time. The aero is in exactly the shape it was expected to be. Corrosion is king and the upper wing surfaces and empennage the most affected. I spent my first full day on the Scotchbrite wheel giving the bubbling paint on the underside of the spoilers what for, followed by the fillet flaps and a bit of the NLG lower scissor link. The upper link is beyond it. I have been getting all the top cowl latches to slide, having to remove most of them to do so, including 5 that were rendered u/s and have to be replaced. Southend is a synonym for helpful. No one is anything but supportive and encouraging in their attitude to the aeroplane and us. Help comes daily from the ATC Lasham Ltd hangar folks, from Ian Dorling, ATC Lasham's Hangar Manager, his engineering team, the stores man, the office staff and down. The list is endless. We have unlimited access to stands, compressed air and tools right down to the most basics like fasteners and masking tape". | ||||||||||||||||||||||||||||

| 10 August 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Norman

King, QFM Flight Operations Administrator, reported from Southend:

"This week has seen steady progress, slowed naturally by the

reduction in numbers to three. All engine and accessory oils have

been drained and replenished, with over 100 US quarts of BP 2380 now

on the account. Our search for spare top cowl latches proved fruitless

so we are in the market for new ones. Negotiations are under way to

hook our office into the Lasham's telephone switch. Again, another

example of the unselfishness of ATC Lasham's Hangar Manager, Ian Dorling.

During the week, we noticed that Lasham's had placed a young lad into

their work experience programme. A fifteen year-old, wide-eyed and

full of awe, he caught Peter's eye immediately. There was a call out

to perform an inspection of the forward side of the pressure bulkhead

bilge area. If you know the size of the crawl space available to do

this on this aeroplane which has the potable water tanks and plumbing

in exactly the wrong place in the aft hold, then you will know that

Peter is not built to perform this inspection. So, young Shaun Bonnett

can tell his mates that he gained some of his earliest experience

on the world's most significant 707. He was chuffed with the cap,

pen and key ring formally presented to him by Bob Phillips. We think

we made an impression on him. A milestone was passed today when the

first system functional check was successfully completed. All four

thrust reversers were operated, courtesy again of Lasham's who supplied

the reverser test rig. Only on one engine did one blocker door hang

up, but with some tweaking, was soon freed up. News that the rig was

going onto the 707 brought out quite a few of the Lasham's engineers

who were quietly surprised at the untroubled functional. Not bad after

6 years, was the comment. What they hadn't seen was the thorough cleaning

of the blocker door slide tracks and the generous applications of

Molykote to anything that slid. We now are close to cowling up, ready

for engine runs. This won't happen until our avionics people have

returned, putting generators on line needing their presence to monitor.

We need to be looking at fuel supply as well. The tanks are bone dry

and we need about 10,000 lbs of fuel to do several things, filling

the CWT for leak checking, transferring it to the wing tanks for their

leak checks, and for the engine runs". Airline operations into and out of the U.K. were thrown into chaos by heightened security checks resulting from a thwarted terrorist plot to destroy multiple airliners in flight. |

||||||||||||||||||||||||||||

| 11 August 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "First, we pause to think of Bob Phillips who is paying his last respects to his Mum tomorrow. Bob, we wish you well on this difficult day. Today we saw a major advance in the cosmetics of the Project. We asked the good Ian Dorling to ring Air Livery Plc to introduce Peter and me and arrange a time to visit them to follow up on the Boeing folk's recommendation that we have the aeroplane painted while in the UK. The result was that within 30 minutes, the Air Livery Plc's Managing Director and Production Manager came to visit us. There was the usual walk around the old girl, a bit of a feel of the surfaces, a look at the number of paint layers revealed in paint removal corrosion polishing and they were satisfied at the size of the job. It was agreed that a total strip was the way to go and they left promising to send a quote later today. To our delight, that they did, but by beginning with "PPG will donate the paint, and another supplier would contribute the stripper, to a total value of £20 000.00." We have cracked a mini jackpot. Later, the e-mailed quote was for labour only, for £70 650.00. which will include polishing all exposed metal. We believe Air Livery is also looking at showcasing their expertise and you can imagine the impact the before and after will have on their company. It looks as if people are wanting to get on the bandwagon. Another exciting development was for us to meet the FEO who operated HZ-123 into SEN on its last flight, to date. His name is Forbes Bradley, and he happened to be in SEN having delivered the 727 on which he is the FEO for a Saudi prince. He will be back later this month and has promised to bring his log book and some pics with him. Some of the day was spent searching the MM and the OHM for the rudder balancing procedure but that chapter is not in our copy of the manual. There was a bit of a win when two hydraulic lines with split B nuts that pass through the MLG torque boxes, one each side, that Peter had estimated a couple of hours to remove came out in half an hour. We were happy about that. Roy Finney, a class of '61 apprentice, joined us today for a month." | ||||||||||||||||||||||||||||

| 12 August 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| QFM Media Relations Manager, Julian Green and his family visited the aircraft today. The Vulcan Restoration Trust performed one of their regular fast taxy runs with Vulcan XL426 G-VJET using fuel which had come from VH-XBA. | ||||||||||||||||||||||||||||

| 14 August 2006 | ||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "Roy Finney was put to work today with a vengeance. By lunchtime, he and Bob Horn had completed installing the balance panels for the left outboard aileron, learnt to drive a cherry picker, made a cable clamp from discarded materials and had done the hydraulic disconnect at the rudder actuator. Roy will be very closely involved with the fin drop. In the morning, Peter and I met again with the MD and Marketing Manager of Air Livery Plc to discuss the windows available for the repaint. Peter will be looking at the 3 ball juggle, involving fin and rudder removal, manpower allocation and paint hangar availability. Air Livery is quite flexible regarding the work flow, and a two-stage program is looking like the preferred option, with the strip, taking 7 days to occur, then pre-flight tasks to be completed, followed by the finish application just prior to fly-away. Their Production Manager took us to the paint hangar and is willing to work his men on a late shift so that we can progress the aeroplane, in the hangar, in the morning. Again, an example of the co-operative nature of our hosts. In another good piece of news, Air Livery has suggested that they will be able to source the vital rudder balancing equipment from another of their customers, Marshalls of Cambridge, with whom they have had previous RAF AWACS repaint experience. In the afternoon, we were paid a visit by one of the designated 707 pilots, Roger Walter, who was on a London trip and dropped over on his slip. It was good to see him so keen, as well as giving him an opportunity to see the engineers at work and to suss out the flight deck layout among satisfying many other curiosities. The effects of the approaching end of summer were felt today, with rain and wind hampering the work flow. Time is becoming the enemy. Late breaking news: Our dear friend Bob Phillips has asked for his return to be arranged. We look forward to his return to the fray." | ||||||||||||||||||||||||||||

| 15 August 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "Roy and Bob Horn got stuck into preparing the fin and rudder for removal. They have been blessed with a perfect set of fin attach bolts, all four free and rotating in their mount lugs. They were expecting 6 years worth of weathering to have made removal a headache but we lucked it. The heads have been scratched with the discovery of only one rudder trim cable turnbuckle where the IPC and MM say there should be two, so new ground will be broken here when it comes to rigging. Peter had great joy in packing all the inop avionic boxes into a huge box for dispatch to SYD. Iain Hodgson seems to be moving things along at a new found pace, hence the smiles on Peter's face lately. A small problem came up today with a crack of serious dimensions was found in the right MLG Upper Shock Strut Door. Our good friend John Sims from Lasham's was only too happy to remove it and organise a repair." | ||||||||||||||||||||||||||||

| 16 August 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Preparations for folding the fin continue. Norm King enjoyed one of those little triumphs which demonstrate the whole team's attention to detail when he repaired and replaced the lateral inclinometer. Having this device serviceable probably means that it will never be required in anger and this should please anyone who has to fuel the aeroplane. Peter Elliott continues to pack miscellaneous components for despatch to Sydney from where they will miraculously reappear fully serviceable. Today the team gave thanks to Boeing for anticipating their needs by designing the undercarriage legs of the 757 to be of sufficient length such that the wing tips of an arriving 757 would overlap those of the 707 thus obviating the need to move VH-XBA out of the way. | ||||||||||||||||||||||||||||

| 17 August 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "More visitors yesterday in the form of our Curator, Karen Glass, and her host while she is here on holiday, Metropolitan Police Constable Sue Dente. Karen promised to drop in some time ago to make us a cuppa, and good to her word, she did. As her reward, we put her to work sorting washers. Later that evening, we all took part in a QFM/ATC Lasham's ten pin bowling challenge at the Kursaal alleys in Southend. It was a great opportunity to begin to repay some of the debt we have to our hosts, and Peter's (QFM's) 50 quid on the bar was much appreciated, and there was a reciprocal gesture from the Lasham's team, that helped the evening along. Naturally, there were lots of comments about Australians bowling underarm, but we took it all in good humour. Hint. Roy Finney and I decided that we'd stick to spannering if another bowling night is suggested. The 707, you ask? There is a campaign to repair the leading edges of all the acoustic liners in the fan exit duct, necessitating the removal of all 12 pieces of the fan extension fairings. Lots and lots of screws hold these panels on, all nicely corroded and firmly stuck in place. Our first enquiry to stores regarding replacements elicited a per piece price of USD12.90 each! We needed 250 of them, or USD3225 worth. Go look for an alternative, please, was the order to the storeman who has now sourced a titanium fastener for USD0.12 each. We are still in shock. Less than 1% of the price of steel for titanium? Don't ask why, just buy them. We were paid a vist today by a British Telecom technician who will install a phone line to the perimeter of the Lasham's hangar. To connect to a Portakabin would involve a huge surcharge, so our Lasham's property person, Keith Terry, has happily volunteered to run a cable from the BT socket at the hangar door to our office about 50m away, gratis. He has even had his man make up the cable. Again, what can we say. Peter and I spent quite a bit of time on the work load allocation and have produced what we both believe is an achievable plan. Getting all the ducks in a row never took on a more important meaning." | ||||||||||||||||||||||||||||

| 18 August 2006 | ||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "Wing plank corrosion work is all but complete from our point of view. Roy Finney and Bob Horn have been getting either a tan or a soaking while grinding and emery mopping the dreaded alloy worm. After the dust has settled, Roy's job has been to plot the depths and dimensions of all the reworked areas, measuring depths to an accuracy of one thousandth of an inch, then producing a drawing of each wing's reworked area. This will then be sent to Boeing's technical services department who will rule on the acceptability of our repair. We believe the material removed will not result in the requirement for patching. If patches are required, our schedule is severely dented. Roy and Bob will be glad to be back on the ground where the delights of sun and sky give way to the even greater anticipation of Skydrol leaks and hissing pneumatic joints. We pressurised the hydraulic reservoir in the afternoon and located a few weeps on #2 engine, which was no surprise, since the oil stains were heaviest there. Mind you, at a reservoir pressure of only 40psi, we really are only tickling a system that runs at 3000psi when the engine pumps are supplying the pressure. They won't do that until the engine runs are performed. A Kazakhstan 757 has arrived at Lasham's for a C Check, which sadly will suck up our volunteers, John Sims and Ken Paice. They have apologised for not being able to assist us for the next few weeks. In addition, there is now a longer queue at the tool crib and the demand for stands and such has increased. We have been spoiled these last few weeks. We paid a visit to the local wheel and tyre overhaul company as well, in the early negotiation stage, to discuss tyre changing. The entire ship set will be swapped for new rubber, 6 years of weather exposure rendering the tyres severely sidewall challenged. We will have to work hard on this one, since although it's quiet in the hangars with everyone flying their aeroplanes hard, the result is that the tyre changers are working at the limit keeping up with the rubber smoke generated by all the summer season landings. Following that, we paid a visit to the nearby spare parts repository, where the fly-home kit was enhanced by the addition of a starter motor. We snagged Peter's hearing this week, it falling below acceptable levels. He attended a local repair station where a flush and declog was successfully performed on his right audio receiver. He now can hear us talking about him, so we need to be more diplomatic than we had been. Old Warden beckons tomorrow, so we will see some aeroplanes even older than ours". | ||||||||||||||||||||||||||||

| 21 August 2006 | ||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "In the country where they invented cricket, I'm sure the people who dreamed up that game factored in the loser's friend - the weather. We had been on track to complete the wing corrosion blending mapping, Roy Finney as keen as any of us to get it done. He was armed with his new Stanley 16ft tape and was about to score the winning run when the heavens opened up and drenched us. Down off the wing, there were other things to do, in spades, so another functional test was completed. While Peter, Roy and Bob worked on the removal of the right inboard aileron, I checked the Emergency Brake system. There were understandably, some defects, but Lasham's had the parts in store to rectify the leak found at a Tee piece, and all was fixed. The aileron has not been as cooperative, with all 3 hinge bolts frozen solid. We won with the rudder mount bolts but the blessings have not been repeated here. Discussion is centred around the purchase of a pneumatic reciprocating saw, the only way out to cut the bolts. The rain today was a real reminder of why English weather is legendary. Good news today is that BT is booked to install our phone line on 29 August, the fin removal gear has cleared customs and should be at SEN tomorrow and Bob Phillips, Denis Martin, Paul Wilkinson and new recruit, Paul Hockey are arriving on tomorrow's QF31. Their presence will be greatly appreciated". | ||||||||||||||||||||||||||||

| 22 August 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "Sometimes a delay can work in your favour, and the QF31 being four and a half hours late allowed Peter a normal start to the day before collecting the welcome manpower increase in the form of Bob, Denis, Paul and Paul. Their renewed presence will allow engine runs to be done, probably Friday 25 August. In preparation for that, Bob and I completed the fan exit acoustic lining rectification and all engines were cowled up and are now only a few hours away from being ready to start and run. That will be a day to remember and it is a great regret that I will miss that by two days. I leave here tomorrow on QF2. One major job was completed today, with the right inboard aileron giving up its grip on the rear spar after Roy's huge effort over the last few days to free up the hinge bracket bolts. It was with great pleasure that the four of us wrestled it to the ground at close of business today. There is some serious corrosion on one hinge support fitting which will require major surgery. The more we look, the more we find. Peter is at least happy that the aileron is off and can be assessed off the airframe. Warwick and two QFM Directors are due here Thursday, so the number of VIP visitors is still on the increase. Before I go, I would particularly like to thank Peter for his confidence in me, Bob Horn for helping me find my way around the base and in pointing me in the right direction on more than one occasion, Roy for his unstinting devotion to his profession and to QFM for taking on this mammoth but achievable task. In the few days that I had been in Bob Phillips company before his compassionate return to SYD, I had come to see a consummate professional at work. This project has brought out so many of the qualities that big achievements need to succeed. Having seen what I have seen, I know we can do it". | ||||||||||||||||||||||||||||

| 23 August 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Peter Elliott reported from Southend: "Well the elegant scribe of the last few weeks is now firmly strapped into the QF2 on his way home. The job of keeping everyone up to date with the latest happenings at SEN is back to yours truly. I must at this point say that Norm King was a pleasure to work with and I feel we accomplished a lot during his stay with very limited manpower. We will be assured that the flight engineer will be able to ensure the lateral attitude of the aircraft is capable of the most finite measurement due the excellent craftsmanship and resourcefulness of Norman King. Jokes, aside, I think Norm thoroughly enjoyed himself, as we all are doing what comes naturally to us, exercising our inherent hand skills to ensure this Aeroplane takes its rightful place in Longreach. Progress was made on removal of the right hand outboard aileron and it is still resisting the attempts of Paul Hockey our new recruit from the land of the other English weather, Melbourne. We feel it will be closer to the ground tomorrow with the offending hinge bracket removed. One of the inboard aileron hinge bolts has been removed with a gentle amount of persuasion. We will continue to work on the other two. The corroded hinge fitting in the inboard aileron is almost removed and hopefully will be on its way to Sydney for all to puzzle over and design a repair. The lifting / lowering slings for the fin/rudder from Sydney were delivered to the aircraft today. Again we will have to call on the generosity of Lashams to help out with some dummy brass pins for the lowering of the fin. The pneumatic system was pressurised today to check for obvious leaks and although minor defects were found, there were no show-stoppers. Fire bottle squibs and an aircraft battery were ordered and we are looking good for an engine idle run on Friday. The avionic team are progressing the boost pump wiring mode and it was discovered today that the Teflon sleeving required to do the job is a shrink fit material so it will make sleeving of the looms a far easier job." | ||||||||||||||||||||||||||||

| 24 August 2006 | ||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

| Peter

Elliott reported from Southend: "The dawn revealed a typical

English day, wet, overcast, rain and wind but we were not deterred,

well almost. Work is still in progress removing the right hand outboard

aileron, with several hinge bolts firmly believing that their rightful

place is attached to the aeroplane. WE will win. Fire bottle

squib installation was completed with the fitment of new squibs, so

in the event of an engine fire we can be certain that we have the

ability to extinguish the fire. At this time, we are looking good

for our first engine run on Friday the 25th August. I am sure the

spectators will be out in force. A new aircraft battery was purchased

and will be installed prior to the engine run. Our avionic team are

progressing the boost pump wiring mod. A local purchase of Teflon

sleeving was instigated so a final decision will have to be made on

the status of the double sleeving after a trial fitment." QFM Chairman, Warwick Tainton, reported from Southend: "I am nearing the end of my five days in London. I took directors John Hamilton and Brian Costello down to Southend to start their volunteer week. Brian had had a flu injection and of course had a corresponding nasty case of flu however Peter tells me he is recovering. John had his son Clive and his mate join him over the weekend." |

||||||||||||||||||||||||||||

| 25 August 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Peter

Elliott reported from Southend: "A great day was revealed on

opening the curtains - blue sky, sun and no wind. Definitely a day

to carry out the first engine run after four years of neglect. The

morning was spent in preparation for the engine run. Firstly, all

engine ignitors were functioned, then engine dry cycles were carried

out to check that oil pressure was functioning. Then a moment of truth

when a wet cycle was carried out to check for possible fuel leaks

prior to the real thing. After this was completed, much to the disappointment

of the gathered audience of Lashams engineers, lunch was declared.

This allowed some of the accumulated fuel in the tailpipe to drain

and dry out. We don't want a blowtorch for the first start. Lunch

was completed and final preparation for the history making event was

under way. Final cockpit checks were done and it was time to "turn

and burn". The run commenced with No 1 engine and after four

years of rest, when the start lever was lifted, the engine accelerated

away to idle that was acceptable with all parameters normal. The next

in line was No 2 engine and again when the start lever was lifted,

the engine accelerated away to an acceptable idle without the slightest

hesitation. You would have thought the engine had only been shutdown

one and a half hours previously after the last sector. There were

minor defects revealed but in general all systems functioned satisfactorily.

Then it was the turn of No 3 and No 4 engines. Again all

systems functioned normally and no major defects were revealed. We

are not out of the woods yet with the engines and all will be revealed

after we satisfy my "lust for thrust"* and the oil filters

are pulled after the second engine run to check on internal engine

health. If we come through that stage with nil defects we can thank

Mr Pratt and Mr Whitney for making such a robust engine that can stand

four years of neglect and still operate satisfactorily. We all

went home at the end of the day with a rather warm feeling inside

and a sense of relief that we have operating engines." * Take-off power! |

||||||||||||||||||||||||||||

| 28/29 August 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Peter Elliott reported from Southend: "The right hand outboard aileron finally gave up its hold on to XBA and allowed itself the dignity of being place on a pair of trestles for further post-operative care by Dr Hockey. There are still two hinge bolts, which are proving extremely difficult to remove. The restricted access to the bolts makes things extremely difficult. The avionic department have struck a problem with the boost pump wiring Service Bulletin as the Teflon sleeving specified is too large to fit in the conduit and it will not suffer a tight bend radius where it exits from the conduit. The problem has been handed to Boeing, as the specification of the sleeving has to be adjusted. ATC Lashams are going to manufacture a couple of dummy pins for the lowering of the fin. We cannot lower the fin until these pins are manufactured. The plan is to have the fin on the ground by the end of this week. Then will start the next episode of stubborn bolt removal. Don't worry, you can tune into this thrilling report of the trials and tribulations of seized bolt removal in "sunny" Southend. The British Telecom man duly arrived this afternoon (29 Aug) and completed the installation of the phone line. The mapping of the corrosion on the left wing is now ready for presentation to Boeing for the official ok or a repair. The right wing should be in the same position tomorrow. This should keep Boeing busy for a while checking the plots. We have had two of the QFM directors here this week checking out progress. They were not allowed to idle their time and were press ganged into service cleaning the cabin area with the chemicals kindly donated by Ecolab. The test of time will see if the smell in the cabin has dissipated. The vinyl in the entrance area was lifted to check if there was water under it and it proved to be perfectly dry so obviously the smell is not coming from there. If the smell continues it will need further investigation." | ||||||||||||||||||||||||||||

| 30 August 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Peter Elliott reported from Southend: "The mapping of the wing upper surface corrosion has been completed and this will be faxed to Boeing on Thursday morning. At last – this has been a big job due to the amount of corrosion caused by neglect over the last six years. The next hurdle will be the analysis by Boeing to determine if repairs are required to the wing. A requirement to carry out repairs to the wing will probably cause a major hiccup in the proposed delivery date to Longreach. The right hand outboard aileron hinge bolts have finally been liberated and all bearings that require replacement have been purchased. The aileron is very sound structurally although the bearings have suffered in the English climate. The hydraulic lines that pass through the torque box area have been refitted with a minimum of fuss and no great heartache. These lines are anchored to a skyhook and Boeing builds the aeroplane around them - well Boeing will dispute that but that is my theory. The fin removal gear from Sydney is being prepared for fitment so all looks good for the lowering/removal of the fin on Monday. We have started to place some components back on the aircraft with the fitment of the left hand outboard aileron tab." | ||||||||||||||||||||||||||||

| 31 August 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Peter Elliott reported from Southend: "The fax to Boeing was sent this morning, so they will have something to occupy them for the next few days. The mapping was done in A3 size and then halved to make it a manageable size. The fin gear was fitted so all is ready for Monday. We will have to move the aeroplane tomorrow as Lashams have an aircraft movement into the hangar bay in front of us. This will cause some lost production. Iain Hodgson, the Qantas co-ordinator of the project paid us a visit on Monday and again today. He has been in the UK on business so he paid us a visit to see how things are being done and to advise on progress with the repair of components currently in the Qantas system. He had some good news with the arrangement of a supply of tyres, 8 main and 2 nose being shipped from Sydney this weekend. We have to now arrange the fitment of the tyres but that will not be an impossible task. The manpower situation is still critical but there may be a light at the end of the tunnel. John Hamilton decided we needed to be on sky cam so he hired a Cessna 150 for half an hour of photography with several low slow passes over the 707 with the gathering of all engineering staff on the wings trying to hide the green patches where the corrosion had been ground away. He stated it was successful so it will be interesting viewing on the video. Shaun Bonnett, the young lad who helped us out with inspection of the bilge area behind the potable water tanks in the rear baggage hold, has returned from his holiday in France so he will be returning to school next week. We will visit tomorrow and drop off his little helping hand on the way to becoming an Aircraft Engineer. Young kids that show potential have to be encouraged. More on this next report. Well it is time to go and check what culinary delight awaits us in downtown Southend tonight." | ||||||||||||||||||||||||||||

| 01 September 2006 | ||||||||||||||||||||||||||||

| Peter Elliott's 70th day on duty at Southend. Thank you Peter! | ||||||||||||||||||||||||||||

| Peter Elliott reported from Southend: "The week has ended on a high note with all hydraulic leaks repaired and leak checked with no further defects. The leak in the left hand leading edge was repaired as per a standard flareless union repair. The brakes were bled this afternoon and all came up with a pass. The taxi test may result in further brake problems but we can only hope all will be ok. The No 1 ac pump complained with a few groans when asked to do some work but once the air was out of the system it performed ok. We have ended the week on a high note with the expected arrival of tyres next week and the return to serviceability of the hydraulic system. Lashams had to play musical aeroplanes today, which resulted in some lost time with the aircraft. The hangar bay in front of where we normally park will be filled with a C check for the next few weeks so this will leave us in peace for a while. We will have to convince the tyre company on the other side of the airport to do us a favour and do the tyre changes for us. The French Supervisor in charge of the workshop (Fred) may have to experience a fine drop of Australian red wine to help convince him of the qualities of this project. The next big step is the removal of the fin, so watch this space for the next enthralling episode from sunny Southend by the Sea." | ||||||||||||||||||||||||||||

| 02 September 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| There

is another Boeing 707 at Southend. This aeroplane is the former Pan

Am 707-321C N473PA "Clipper Pride of America" (msn 19375)

which has been stored at Southend since 1998. Any possibility that

the aeroplane might fly again ended on 3 May 2003 when vandals set

fire to the cockpit. The aircraft was last registered EL-AKJ to Omega

Air. Its most recent operators include Occidental Airlines and Skymaster

Airlines of Brazil, who still operate the former VH-EBN. UPDATE 25 March 2007: The engines were removed from EL-AKJ on 15 March and the rear fuselage and tail were cut off on 16 March 2007. UPDATE 28 October 2008: Added an image of the aeroplane being dismantled on 17 March 2007. Within two weeks, all traces of the aeroplane were gone. |

||||||||||||||||||||||||||||

| 04 September 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Peter Elliott reported from Southend: "The week started slowly when on our arrival at the airport, we found XBA parked in the reverse position to normal. On Friday we had to position our aircraft to the Eastern bay to allow the aircraft Lashams had in the hangar out for engine runs and departure. We worked the aircraft in its present position with the final grind of corrosion wrapped up by the corrosion crew - Bob Hagon, Bob Phillips and Roy Finney finally hanging up their die grinders. It's a job no one enjoys but something that has to be done. They were ably assisted by the surgeon/artist in residence, Da-vinci Hockey, on the green primer brush. It is a pity the fine brush work will be lost when a coat of colour goes on the aircraft. The final plot of corrosion removal will be faxed to Boeing for consideration. John Hamilton completed his work experience at the Southend B707-138 repair base and he will depart for Oz on QF2, 05 Sep. He went away with a clear understanding of the size of the project. Both John and Brian thoroughly enjoyed cleaning of the interior and the polishing of the engine cowls - I hope!" | ||||||||||||||||||||||||||||

| 05 September 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Peter Elliott reported from Southend: "Tuesday started on a high note with Brendan from Lashams stating their crane was back from repair and we would be able to use it. So, armed with that info, we prepared to lower the fin... It is now 1513 hours as I type this and the fin is still firmly attached to the aeroplane. Lashams have multiple aircraft movements today so we are very low down the pecking order of things. They have to look after their paying customers first. With a little bit of luck we may be able to complete the fin removal tomorrow, depending on our host's workload. The forecast winds for today and tomorrow are 5-10 knots - satisfactory for removal of the fin, so keep your fingers crossed we may have the fin sitting on the ground tomorrow. The donated tyres have arrived in LHR so we will have them at SEN on Thursday. I approached Aviation Component Repair Services again to see if they could do the tyre changes and they can fit us in and as well, have agreed on a very good discounted rate. Once the tyres have been delivered, we will commence cycling them through to have the new rubber fitted. We need volunteers now to blacken the tyres. We have to have this aircraft looking better than JT's. That's about all from the land of the permanent clouds." | ||||||||||||||||||||||||||||

| 06 September 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Peter Elliott reported from Southend: "Ladies and gentlemen, the fin is on the ground and we did it without bending it or the aircraft. The day started with a rush with the first part of the procedure laying the fin over 90 degrees to the right and supporting it with a strut. Next, Lasham's crane was positioned and an attempt made to lift the now horizontal fin off the fuselage. Despite several attempts, it would not depart its hold on its mother. The crane from Lashams was proving limited in capacity and we could not remove one of the dummy brass pins. It was decided to call lunch and investigate the reason for jamming the pin and the 1/2 inch brass drift in the fin mounting lug. The fin was left attached with the 1/2 inch brass drift and the dummy pin. After lunch was finished, the fin had not departed to earth so a large crane from outside was organised with a 30 meter jib extension and 25 ton lifting capacity. I don't know the cost but I'd say it will surely dent the budget. This crane arrived at 1450 and the fin was removed and firmly attached to its transport trolley by 1537, thanks to a great effort by Bob Horn (The Quiet Achiever), Bob Hagon (The 707 Guru) and Roy Finney (The Fin Man). They persevered against difficulties without a complaint. By the way, the photos you will see have been digitally edited to ensure no one thinks these blokes were taking any undue risks. The end of a great day-- THE FIN IS REMOVED. O&O from the land of permanent clouds." | ||||||||||||||||||||||||||||

| 07 September 2006 | ||||||||||||||||||||||||||||

| Peter Elliott reported from Southend: "Another day in sunny Southend-on-Sea. The reinforcements arrived today - Al Chong, Dave Short and Bob Hodsdon. Both Al and Bob have had a previous tour of duty at Southend so they know what to expect. Dave is new to the effort to save this aeroplane. Progress was made on the removal of the rudder from the fin with all balance panels removed by knock-off time today. I have located a rudder sling at Cambridge (Marshalls) and they have agreed to the loan, so providing we do not have numerous bolts seized we might see the rudder liberated from the fin in the near future. Note I did not stipulate a day. The flap rigging was completed today. For this task, we'd normally connect an external hydraulic test unit, a large capacity pump usually driven by a petrol or diesel engine. Unfortunately, Lasham's hydraulic rig is electric powered and it did not have enough power lead to reach outside the hangar. The only alternative was to use one of the aircraft's engine driven pumps, so we started No 2 engine to provide the flap system hydraulic pressure. Not the cheapest way to rig the flaps but it required a full 3000 psi and plenty of flow to ensure the flap rigging was correct. So, for the second time in this exercise, No 2 engine started and idled OK with no obvious defects. The next step will be a power run to get a true gauge of the engines. Roy Finney, a tower of strength on the Heavy Maintenance work, departs for home tomorrow. He was running around on top of the fin yesterday like he was an apprentice again. A big thank you from the Board of QFM and the 707 Team. O and O from sunny SEN." | ||||||||||||||||||||||||||||

| 08 September 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

|

Peter Elliott

reported from Southend: "The day we have all been waiting for

- a serious engine run. It is time to test the LRTs to see if they

can muster enough grunt to propel the old girl all the way home.

The day commenced with a phone call to Marshalls of Cambridge to

confirm their rudder sling was available for use on XBA. Not only

did they lend it but also they arranged for a delivery to SEN by

the afternoon. Once again, companies all over the UK are only too

willing to come to our assistance. The rudder was ready to remove

at lunchtime so it appears we will not have a marathon for the removal.

After lunch, as we approached Lashams hangar, the storeman handed

us a present of a box containing two slings, one for the rudder

and one for the elevator. We are so taken with the support offered

from local companies which has just been above and beyond. The aircraft

was prepared for the move to the engine run area, taxiway Bravo,

not far from where she spent her last six-year holiday. Lashams

provided a tug and crew for the move and once again, where would

we be without this company? Nothing is too much trouble. Half our

team drew the short straw and had to stay and progress the rudder

removal. Thanks to their hard work, when the engine run was completed

and we were towed back to the allocated position in front of Lashams,

there was the rudder sitting on its own transport stand. A job that

was done with a minimum of fuss and no great difficulty. An interesting

point was discovered - when No 3 hinge was removed, it was impossible

to turn. Just as well the rudder has a large hydraulic actuator

to move it otherwise it would never have moved. Well, I suppose

you want to know the results of the run.

Definitions

O&O from PE and the team in sunny S-o-S." |

||||||||||||||||||||||||||||

| 11 September 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| 13 September 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| 15 September 2006 | ||||||||||||||||||||||||||||

| Peter Elliott's 90th day on duty at Southend. Thank you Peter! | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Peter Elliott reported from Southend: "The important milestone of landing gear retraction and emergency extension was hit today and all worked as per book. This week has ended on an important high, with the rudder hinge fitting support finally being removed from the fin after three day's hard slog. All we have to do is find a new one from somewhere. Sorry there has been no daily report for a few days, but this week has been very hectic. Bob Hagon departed today after his second stay trying to save XBA. Thanks Bob for your continued effort and help. Regards, Peter." | ||||||||||||||||||||||||||||

| 19 September 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| 20 September 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| 22 September 2006 | ||||||||||||||||||||||||||||

| Alan Chong reported from Southend: "Gday from Sunny Southend on Sea. Peter Elliott is currently returning to Sydney for a well earned rest after almost 100 days on the job. We welcome Ernie Wearne and Bill Hill to our team this week. Structural repairs to the fin are almost complete. Drilling and attachment of the rudder hinges will commence next week. Rudder attachment will have to wait for delivery of the centre hinge support fitting . Marshalls will arrange free delivery of the fin paint fixture tomorrow which will allow painting of the fin and rudder on the ground after repair. Hinge fittings for the rudder arrived today but require precision drilling, so jigs will need to be manufactured to ensure a good fit. This will keep us busy while painting is in progress. Number 2 and 3 engine fuel pump and fuel control unit filters were removed, checked and found clean, so no major mechanical failure of the pump / FCU was evident. Qantas Stores at Heathrow advise that the shipment from Universal will also arrive in the next few days." | ||||||||||||||||||||||||||||

| 23 September 2006 | ||||||||||||||||||||||||||||

| Alan Chong reported from Southend: "Gday from a very wet Southend on Sea. Well it rained all day for the first time in a while. Peter must have known it was coming and yes, our hangar roof leaks. Structural repairs to the fin centre rib are now completed and awaiting the arrival of the hinge support fitting. The stubborn right hand outboard aileron hinge support has now been removed after great effort by Paul and Bill in the wet. Entry door lubrication now completed. Air Livery now report that their hangar is not available until Thursday owing to difficulties painting the B-17. Painting is now scheduled for Thursday 28 September. Today was Bob Phillips' last day on the job. He will depart for his tree hugging course on Sunday and will be greatly missed by the girls in the canteen and the hotel and all of us of course. Can somebody with influence convince Mrs Phillips to allow his return. The fin support fixture hasn't shown up yet but hopefully it will be here on Monday. Stores advise more avionic parts should also arrive Monday." | ||||||||||||||||||||||||||||

| 25 September 2006 | ||||||||||||||||||||||||||||

| Ross Downes reported from Southend: "Baptism of fire over. Welcome to the project, Rossco. Rainy day to start us off, even better. Steve Jones of Air Livery confirmed that the aircraft will go into the paint shop on Thursday afternoon for seven days. The rudder and aileron hinge fittings have been received and sent to the shop for drilling. The rudder/fin support stand has been promised for tomorrow or Wednesday so we should be able to work on the fin and fit the rudder while the aircraft is in the paint shop. Flap lubes are now completed and corrosion rectification to the fuselage has been done prior to painting. Avionic parts have been packaged and despatched to Sydney. All in all a busy but fun first day. I think I have been smitten by the old girl already." | ||||||||||||||||||||||||||||

| 27 September 2006 | ||||||||||||||||||||||||||||

| Ross Downes reported from Southend: "One sheet metal guy was borrowed from ATC Lashams for 4.75 hours. More rudder hinge fittings have been received from the work shop after drilling. The right hand outboard aileron hinge bracket has been fitted and the aileron can now go on tomorrow. A repair to the left hand forward fuselage was completed prior to painting. The left hand main landing gear door has also been rapaired. The nose landing gear steering cables have been cleaned and lubricated. The left hand outboard aileron cable was also cleaned and lubricated. Many portable oxygen bottles and other avionic parts were received. Tomorrow we hope to fit the right hand outboard aileron and repair the right hand air conditioning door prior to painting." | ||||||||||||||||||||||||||||

| 28 September 2006 | ||||||||||||||||||||||||||||

| Ross Downes reported from Southend: "Well the old girl has gone into the paint shop today and should come back out as good as the day she was built. The rudder hinge fitting has left the States on Fedex. The right hand outboard aileron is back on with the balance panels still to go. Olin Binge will go out and buy an anti-skid shield he has found with the correct paperwork for $2200. The right hand air conditioning door repair has been completed prior to painting. The left hand main landing gear door sheet metal repair has been completed. Aileron build up has started." | ||||||||||||||||||||||||||||

| 29 September 2006 | ||||||||||||||||||||||||||||

| Ross Downes reported from Southend: "I spoke with the paint shop supervisor today and they are going to strip and treat the top of the wings. I also asked if they have the time and some spare paint if they could scuff and roller the top of the flaps but I am not sure if that will happen. Colin Binge has come up with an alternative for the missing rudder panel so we have asked for a photo to see what it looks like. The right hand inboard aileron is back together and ready to refit. The remainder of the rudder hinges have been fitted. We are now working on clearing up cowl defects until the bird comes back out." | ||||||||||||||||||||||||||||

| 02 October 2006 | ||||||||||||||||||||||||||||

| Ross Downes reported from Southend: "The painting of the aircraft is coming along. Stripping is completed. The fuselage inspection found only minor defects which have been rectified. Barrel sealing and treatment has been completed. Colin Binge has been requested to buy the missing rudder panel as photos have been received and it looks ok. The rudder hinge fitting has arrived in Sydney for rework. The replacement upper scissors link for the nose landing gear has been received. The second closure rib and skin have been removed from the lower rudder. We are working on defects where we have access to the aeroplane." | ||||||||||||||||||||||||||||

| 06 October 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Alan Chong reported from Southend: "Gday from Soggy Southend. It rained all day so it was lucky that the aircraft was in the hangar while the paint was wet. Val Wearne is still here with no space on flights for the next few days. No work was achieved today as the rudder hinge fitting is holding up the works. The aircraft exited the hangar late this afternoon sporting its original livery. It's amazing how a little paint can make an old girl look good." | ||||||||||||||||||||||||||||

| 09 October 2006 | ||||||||||||||||||||||||||||

|

Media Release by the Australian Minister for the Environment and Heritage, Senator the Hon. Ian Campbell. Historic 707 still calls Australia home Australia’s

first jet plane – a 1959 Boeing 707 and the oldest in existence

– will return home next month to become part of the nation’s aviation

history, following a grant of one million dollars from the Australian

Government, the Minister for the Environment and Heritage, Senator

Ian Campbell, and Qantas Chairman Margaret Jackson announced today

in Sydney. |

||||||||||||||||||||||||||||

| 23 October 2006 | ||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "Dark and damp. A familiar scene replays as we taxi in to begin my second session at SEN. I had left a late summer behind two months ago but now I'm reminded that in the UK, months that end in ---er are best spent in the other hemisphere. A text message from Peter tells me to look for my pickup at Starbucks and soon we are on the M25 heading for Westcliff, the Erlsmere Hotel and home for the next few weeks." | ||||||||||||||||||||||||||||

| 24 October 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Norman

King, QFM Flight Operations Administrator, reported from Southend:

"Three full cars drop off their loads of workers at SEN and as

I walk onto the hardstand I confirm my opinion that an aeroplane minus

its vertical stab, no matter how fresh the paint, is not a good subject

for photography. I can't wait to help the experts put the tail back

on, which is one operation for which we need good weather. It won't

be done in the rain. Within minutes, the team is at work all over

the aeroplane, the Boeing engineers from Amberley adding a huge presence

to the bustle that is now the mood here. They also have the biggest

tool boxes you have seen. During the day, the Marshalls of Cambridge

engineer arrives and performs the rudder balance and tells us that

will probably be his last since he's about to change employers and

move to Norwich to start with KLM. All the best, Gary and thanks for

adding to the history of XBA. Roy Finney and Bob Horne trundle the

rudder out of the hangar and all of us lift it to flop it over as

it is brought up next to the fin ready for reattachment. Funny how

most of us wanted to go to the light end to lift leaving Peter at

the base. At lunchtime, Denis Martin, Paul Wilkinson, Dave Short and

I begin some functional testing of (tech speak for playing with) the

FMS. This of course reveals a snag that will require yet even more

manhours to solve. Typical of this phase of the operation, as components

are returned from overhaul, installed then functionaled, glitches

appear. Frustrating, but reality. Fresh in this morning on the QF31

is Peter Asplin who awaits us as we return home. Welcome, Peter. The

forecast is for rain tomorrow." Thanks to the Boeing Australia Team |

||||||||||||||||||||||||||||

| 25 October 2006 | ||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "The Team held a progress review today and regretfully rolled the fly-away date to the right. The factors that drove that decision are myriad, with weather deterioration, lethargic parts supply and system failures occurring during functional checks the predominant causes. For example, the F/O's #2 window produced sparks and smoke when the window heat test was being done today. The bus bar overheated and to make sure we had a completely dead window, several cracks radiated in the outer pane from the bus bar hot spot. Waking an aeroplane from a 6 year deep sleep is problematic. On the plus side, the rudder was attached to the still horizontal fin today and another day's work to panel up and connect all the linkages should see it ready to mount. Avionics work continues to reveal odd problems such as attitude warning vane heating inop but Denis Martin, Paul Wilkinson, Norm Mackay and one of our Boeing engineers, Brett Godby have been having more success than not, so are confident heat will be soon restored. Our Patron, Ron Yates, in Paris for a safety conference, has called to say he will visit on Guy Fawkes Day, 5 November. Jeff Watson is filming at present and has welcomed the chance to grab some history on film as Ron is reunited with his 'baby'." | ||||||||||||||||||||||||||||

| 26 October 2006 | ||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "Peter Asplin has refreshed his 707 skills over the last two days and has been part of the fin and rudder team with Roy Finney, Bob Horne and me working all day on the vertical stab. Hundreds of new fasteners and 8 hours later, we are 99% on the way completing the build up and are confident that if the weather and crane stars are in harmony, we will mount on Monday. In good news today, we determined the air conditioning packs ran successfully and that #2 Turbocompressor is operational when a new shut off valve is installed. Just to balance this good news off was the discovery of cracks in the diffuser cases of both #1 (serious) and #3 (minor). Speculation is that heat treatment after repair prior to the last C check manifested itself after our recent engine runs. One step forward... " | ||||||||||||||||||||||||||||

| 27 October 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "A clear but cold day dawned, with 0700 showing the promise of some sun. As Jeff Watson said, it looked like an f16 at 1/200 sort of a day. The last of the overhauled main wheels were changed this morning, Roy Finney and Peter Asplin playing the starring roles as cameras rolled inches away from their faces. A bright morning brought another bright spot in our day with our Curator and nominated Flight Attendant for the return Karen Glass, visiting this time with a huge tin of Anzac biscuits to share. She and Ken Cannane went through the many aspects of running the cabin and contributed greatly with her knowledge of things CIQ, especially with regard to the quarantine regulations applicable to the US. Ken was most impressed with her professionalism and knowledge. The fin prep was completed and at last some panelling up was commenced with many square feet of wings and struts now a bit more aerodynamic. A sizable number will do a day's work tomorrow to try to drag back a few of the lost hours. The request for a crane to lift the fin is in limbo, and we await the lifting company's reply. Robert Phillips returns to the fray on Sunday. Sydney's answer to the diffuser case cracking is still to come but looks as if it will be OK to do provided it's patched over the weld." | ||||||||||||||||||||||||||||

| 28 October 2006 | ||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "With the setbacks of this last week in mind, 6 of us took the decision to work XBA today (Saturday), in an attempt to scrabble back some of the time-shift the project has taken to the right. Peter Elliott, Bob Horne, Roy Finney, Norm Mackay, Fab Romanin and I made a leisurely start to the day and at 0915 were at the aircraft with outboard aileron lockout hook up and aileron rigging for the framies and fuel flow indication rectification for Norm Mackay, the aim. Fab Romanin came out to knock over a few more sheet metal repairs. The weather was good with fair skies and sunshine to greet us and things appeared to be progressing well. Norm Mac found a wiring problem that was the cause of #2 fuel flow indication creeping at 500 lb/hr with the engine static while the aileron work was carried out. The flaps had to be raised and extended many times to allow the aileron work to progress and we had almost completed our tasks when, during the final flap operations there was a disheartening call to switch off the #1 Aux Hydraulic Pump because hydraulic fluid was spraying in the right wheel well and we were losing Skydrol - yet again. Result? Work that had only been done yesterday to button up the area of the leak had to be undone and the offending line removed and repaired. Frustrating to say the least but we were in the end, ahead by a day, the B nut due to split on Monday when this work would have been done. The line is now removed and the repair complete with only (!) the installation to go. Aluminium B nuts will be near top of our Most Trouble Inducing Component list. With this, we departed to launder our Skydrol soaked gear and a take a bit of a weekend break. Sunday will be a full day of rest." | ||||||||||||||||||||||||||||

| 30 October 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Norman

King, QFM Flight Operations Administrator, reported from Southend:

"The crane Peter had ordered was waiting for us as we walked

onto the hardstand at 0800, the first sunrise of this post-daylight

saving period promising a fine morning. Nil wind, eager workers who

had been going over it in their heads in bed before going to sleep

(thanks Bob Horn) and a professional crane driver set the scene. This

was going to be a significant day, no doubt. Ben Hunter scaled the scaffold to attach the crane to the sling, jumped down and slowly the tension increased in the cable, and the fin and rudder were on their way. Ready on top of the fuselage to receive the one ton lump were the aptly named Roy Finney, his doubles partner, Bob Horn and not to forget that there are electrons involved in this, Paul Wilkinson, gloved up and ready to hook up the 7 electrical connectors for radios and yaw damper. On the ground, a dozen cameras were there to ensure no angle went uncovered. Jeff Watson and Dave Telfer, his cameraman made sure we all looked like amateurs but our website pics come free. It is now about 0810 as the fin approaches the height where mount forks and lugs must meet exactly in order for the pins to slip into the holes that marry the fuselage and vertical stabiliser to form one unit. So well rehearsed were this trio that with only about half a dozen hand signals from Bob, the satisfying clunk of the first pin sliding into place was heard only 5 minutes after the two pieces gently came into contact. If ever an engineering operation started smoothly, this was it. The minimum of fuss that went on was probably a bit of a disappointment to the documentary makers but to us, it was pure magic. At this point, attached by the right side pins but still horizontal, our fin is held level by the crane but a jury strut has to be installed to hold it so, while the crane is disconnected. Again, a few deft movements with the required links and the strut is in place and we hold our breath while the crane jib is lowered and the cables go slack, the strain now taken by the bright red strut. Forty minutes after he has hooked up, and £550 later, the crane driver is on his way, oblivious to the perfection he has just witnessed. Next, the fin has to be raised through 90 degrees to the vertical position and the left mounting pins installed. To do this, we again call upon our ATC Lashams friends and a tractor and driver appear as Roy and Bob erect the A frame that will add the mechanism to allow a cable to be connected to the tow bar that will pull the fin up to vertical. Another pause for breath as the tractor reverses and the new cable tensions up under the weight of the fin as it slowly transfers the strain from the jury strut. When exactly the right force is applied, the strut can now retire and again, it's with the pretty-to-watch economy of motion of the fin boys that the strut comes off and the tractor driver's skill is now the key to success. He creeps it backwards and the fin now starts its upwards arc, the big worry now to restrain it from going over-centre if it goes past vertical. To prevent this, the tug-o-war team is pulling on a rope in opposition to the tractor, they on the right and the tractor on the left but there is once again the beauty of a team doing what it's perfected in the mind and the gentlest of clunks announces the meeting of the left side lugs. It's up. The final bolt installation is mere routine and at 0940 the fin is declared bolted in place. The statement this makes is enormous. A sense of real achievement settled on us and the smiles are back on many peoples' faces, the biggest of which is now on our Engineering Manager's face. In other news, the hydraulic system is contained again, with Saturday's leak repaired and tested. Peter had planned an engine run late in the day but in the usual manner, sod's law applied with the one and only Ground Turbine Start Unit, GTSU, unavailable because it had been taken to London City Airport to rescue someone whose APU must have failed. Tomorrow. The day ended at The Fisherman's Wharf which rang to the sounds of 16 very pleased engineers, one wife and visitor Bruce Chivize from Qantas Engineering as we toasted the Boeing contribution and wished them and Dave Short, our radio volunteer, God speed, and paid tribute to Bob Horn and Roy Finney, and Paul Wilkinson for their slick act in making XBA look like a real aeroplane again." |

||||||||||||||||||||||||||||

| 31 October 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "After yesterday's brilliant sunshine, today dawned with that light in the sky that said "Rug up". The visual progress so beloved of Qantas engineering managers of the '60s was a tad absent today, but with yesterday's statement standing 44 feet tall, we could be forgiven. We did however, make an audible statement with idle engine runs done to prove Fuel Control Units, leak check fuel systems, run airconditioning packs, tubocompressors and provide some entertainment for Jeff Watson. Nothing spectacular, but added up, the project went forward with no backward steps taken. QFM Director John Hamilton phoned to check on progress and told us that it was 38 deg back home. Here it was 10 deg at the end of the day. Thanks, John. A little distraction appeared in the form of a Monarch 757 that went past the corner of my eye at a speed I thought meant take off. I stepped back to look at it, expecting to see it rotate. Instead there was a huge cloud of dust as it came to a stop which couldn't have been far from using Woodbury Lane as a taxiway. About 30 seconds later the firies sped past and there was a discussion in which "smoke" was mentioned. From the pilot's underpants, was the riposte from our group. Nevertheless, something to think about for our operation. SEN is not too long." | ||||||||||||||||||||||||||||

| 01 November 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "Twelve Michelin Men descended on XBA today, bucking a 25kt headwind on the way to the the hut with the promise of only weak sunshine to add some warmth. Nevertheless, since the fin went on, the mood has been decidedly upbeat, with the sense that the end is in sight. As Peter has said, it's only a lot of 5 minute jobs remaining. As if. We have had the pleasure of having had one of our Sydney Qantas Engineering contacts drop in to spend some time on the job with us. Bruce Chivizhe has been with us for three days and the famous 707 magic has been woven after he walked a few days in our remote, distant shoes. That tyrannical distance so beloved of authors is now very real to him. All the same, it was good to be able to refine some of the processes that should see speedier parts delivery result. Bruce departed this afternoon with a bag full of notes and his To Do file bursting. On the aeroplane, there wasn't a lot to see for the effort put in, with the highlight of the day being the Air BP bowser's visit to put 14 000 litres of fuel into the 4 main wing tanks. This gave us the chance to look at tank integrity after some component changes and all went well as far as leaks were concerned. What did show up was a gauging problem with #2 Main Tank that has been problematic from the beginning. Where 6100lbs should be indicated, it's reading 3800lbs. More head scratching for the avionics guys. After daylight saving ended, we have discussed moving the work day start time forward, so as to stay in the daylight at close of business. The sun goes down around 1700 now, and the last half hour of our current day needs torchlight to complete. In the sense of unity, all agreed to give it a trial. Great to see all pulling in the same direction. Tomorrow is forecast to be 3C min and 10C max with a 10 kt North Westerly. We can handle that." | ||||||||||||||||||||||||||||

| 02 November 2006 | ||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "Today saw more panels going onto the aeroplane with the corresponding increase in floor space in the office a heartening sight, not to mention convenient. This has become the progress indicator of the most tangible kind and all have a look in their eyes that says the sense of completion is kicking in. Areas progressed today include the continuing diagnosis of the #2 Main Tank Quantity Indication defect, which Denis Martin unfortunately believes is due to a defective Compensator. This means a tank drain, ventilation of 24 hours before humans should get in, maybe 12 for avionics personnel, a few hours to swap out the component, refilling the tank again and calibration. Assuming we can purchase the part within the week, that means another sizable dent in the schedule. On the diffuser case cracking, we have a promising lead into Turbine Motor Works, in Cambridge, who are responding in very much the way all our UK providers have, with a can-do attitude which seems to follow any mention that the work is on our rare and historic aeroplane. We are becoming quite good at pleading our case. Cold but less wind made it a better day." | ||||||||||||||||||||||||||||

| 03 November 2006 | ||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||

| Norman King, QFM Flight Operations Administrator, reported from Southend: "Last night, Craig our friendly chef did a special meal for 14 of us. A plate piled high with roast turkey, vegetables, cranberry sauce and roast potatoes stopped us in our tracks but somehow we managed the apple pie and ice cream that followed and then put in a super effort to clean up the cheese plate for a finale. I can't speak for everyone, although I'm sure most would agree, that this was the closest thing to home cooking we'd had for quite a while. It's these simple things that make such a difference to the overall morale and another dining-in night is planned again for next week. Oh, and four bottles of a French red disappeared during the night's feasting, as well. So, on full tummies, first thing this morning, more pics of the engine cracks were sent to the potential repairer, Turbine Motor Works of Bury, Cambridgeshire. By 1100, they responded with the good news that they can do the #1 engine diffuser case repairs. The bad news is that they can't do it on the wing. Heat treatment to normalise the area where welding will be done is not possible in the open. The good news is that yet again, our best friends here have a complete bootstrap engine change gear kit, an engine stand, the works. The best news is that by 1645, the engine was in the transport stand and ready for collection. TMW has put a 3 day turn time on it with return next Wednesday. With that efficiency the filip, once again, the team spirit took over, with all hands to the winches and more Pratt and Whitney JT3D engine change experts on hand than had been gathered since 1968. With fading light, the tools were put away and a satisfied band of weary workers plodded off home, the prospect of a day or two off lifting their mood. TMW, by the way, overhaul RAAF 707 engines. Our mate Frank Bowden, one of the quiet generation who do and don't trumpet, leaves us today after a three week stint grafting away at the regs side of the project. To relieve the, um, boredom he got out and about to help with panelling up but more importantly, he has packed up many stray components into manageable sized boxes ready for either shipping or carriage on the delivery, which has made the office much more habitable. Thanks Frank, travel safely and may your creaking joints recover soon. An eventful end to a great week." | ||||||||||||||||||||||||||||

| 06 November 2006 | ||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||